VISTA volunteer Rachel Rush lighting the pile for the colliers/NPS

Editor's note: At Hopewell Furnace National Historic Site in Pennsylvania, one of the key jobs was making charcoal for use in firing an iron furnace. Tom Straka, a forestry professor at Clemson University in South Carolina, also works as a volunteer "collier" at the historic site. In the following post, he explains the process that goes into making charcoal.

Hopewell Furnace National Historic Site is an example of a charcoal iron plantation. Charcoal was the fuel of the iron furnace and its production was an integral part of the plantation. Several times each summer, in a small fenced-in area west of the charcoal barn, colliers, or charcoal makers, practice the art of producing charcoal using a charcoal pit.

This is the traditional method of making charcoal and the same method used at Hopewell Furnace since 1771. Charcoal burning is usually scheduled for May and August. Curious visitors are often attracted to the large black mound that produces much smoke, and the colliers are accustomed to being queried on what they are actually doing. Below are typical questions visitors commonly ask, followed by the responses of the colliers.

1. What are you doing?

We are making charcoal, the fuel used in iron making. The person in charge of charcoal making was called a collier.

2. What is charcoal?

Charcoal is the solid black wood residue produced when wood is burned in an enclosed setting where air (oxygen) is restricted.

A diorama of an exposed charcoal pit. Note three tiers of wood and a chimney built in the center, with a dirt covering to seal the wood from the air./Doug Page)

3. What is burning inside that black mound?

Under that black material is a densely packed pile of wood, called a charcoal pit. The black layer seals the wood from the air, allowing it to be 'baked or roasted' and this incomplete combustion produces charcoal.

4. What exactly is that black layer and how thick is it?

That black layer is charcoal dust left over from old charcoal pits. The two-step process of covering the wood pile is called leafing and dusting. First, a thin layer of leaves is put on to prevent dirt from reaching the charcoal and fouling it. Second, the pit is sealed with a thin layer of dirt or charcoal dust.

5. Why did they locate the furnace here?

The location has all the four necessary ingredients for iron production nearby: iron ore, limestone for a flux, flowing water, and trees for wood to make charcoal.

6. Why didn't they just use coal as the fuel?

At the time Hopewell Furnace operated charcoal was the only suitable fuel for an iron furnace.

7. Why not just use wood as the fuel instead of charcoal?

To smelt iron the furnace blast had to consistently burn very hot. Charcoal burns much hotter than wood (even seasoned wood) and at a more consistent temperature.

8. How was the pile constructed?

Under the charcoal dust and leaves is a neatly stacked pile of wood. A small triangular chimney in the middle provides support for the pile, ventilation, and a place to ignite the fire. Four-foot pieces of wood were then stacked against the chimney, slightly leaning inward so the wood pile could be a mound that would hold a layer of charcoal dust. The charcoal pit might have two or three tiers of wood (thus be 8 feet or 12 feet tall).

9. Is this where the charcoal pit was originally located?

No. The charcoal was made in the woods where the trees were growing. Charcoal is much easier than wood to transport and store as it has one-third its weight and one-half its volume.

10. How do you light it?

The charcoal pit is lit at the top of the chimney with a shovel or two of burning coals from the campfire. Once the fire is going well, the chimney is covered with a slab of wood (the bridgen) and the top is covered with leaves and dirt.

11. What happens if the fire in the chimney goes out?

If needed, more burning coals were dumped into the chimney to 'recharge' the fire.

12. How long will the charcoal pit burn?

It depends on the size of the charcoal pit. In Hopewell's demonstration, we use small charcoal pits only a few cords big that will take about a week to 'burn off' or 'come to foot,' ('bake' to the bottom of the pile).

13. Does all the wood turn into carbon?

If the job is done well, most of the wood will turn into carbon.

14. What is the history of charcoal making? How far back does it date?

Man has used charcoal since before recorded time. There are charcoal drawings in French caves that are well over 10,000 years old.

15. So no wood is actually 'burned' in a charcoal pit?

The wood is baked rather than burned. Once the pit reaches about 518°F (270°C), the carbonization process becomes self-sustaining.

16. How hot does a charcoal pit get?

Peak temperature is around 750°F. Under the right conditions it can exceed 1,000°F.

A burning charcoal pit; the pit has just been ignited, so steam is being driven from the wood./Pat Straka

17. What is the smoke coming out of the pile?

If everything is going right, the smoke will be the volatile gases produced by carbonization. At first, white smoke comes off the pile as water moisture is driven off.

18. What happens when holes develop in the covering of the charcoal pit?

Any cracks in the pit cover of dirt and leaves (which are normal in the charcoal making cycle due to shifting within the pile and weather conditions) would be sealed immediately to prevent too much air (oxygen) from entering the pile and causing a 'flame out'.

19. You climb on the charcoal pit with that ladder to fill in holes. Is that dangerous?

The most dangerous aspect of the job was called 'jumping the pit.' The collier had to watch for soft spots or 'mulls' on the 'head' (top) of the pit and, if they occurred, he'd jump the pit to fill in the space created by the mull.

20. Where did the wood come from?

Hopewell Furnace owned or controlled about 4,000 to 8,000 acres of woodland around the furnace, including what is now French Creek State Park.

21. How was the collier paid?

While the woodcutters were paid by the cord, the collier was paid by the bushel or perhaps wagon load. The more charcoal the pits yielded, the more he made.

22. What kind of wood do you use?

Charcoal can be made from any kind of wood. 'Hard' hardwood such as oak, hickory, maple and chestnut make hotter burning charcoal in the furnace.

23. What are the characteristics of good charcoal?

Chaturvedi (1943) defined it as: 'Charcoal of good quality retains the grain of the wood; it is jet black in color with a shining luster in a fresh cross-section. It is sonorous with a metallic ring, and does not crush, nor does it soil the fingers. It floats in water, is a bad conductor of heat and electricity, and burns without flame.'

24. What factors influence the rate of burning or carbonization process?

Main factors were (1) type of wood (hard hardwood trees were best), (2) size of the wood pieces, (3) wood condition, (4) moisture content of wood, (5) ground condition, (6) time of year, and (7) weather conditions and temperature.

25. Does the charcoal itself have moisture content?

Charcoal straight from the pit contains very little moisture, but this quickly increases to 5 to 15 percent once the charcoal is exposed to air.

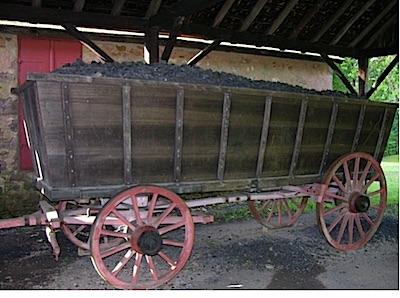

Charcoal wagon under cooling shed at Hopewell Furnace. The charcoal wagons were built so that if the charcoal was not sufficiently cooled, the bottom of the wagon could be very quickly opened and the load of hot charcoal dumped on the trail. This bottom opening was also used to empty the wagon at delivery/Pat Straka

26. What happens to the charcoal pit if it rains or is windy?

Once the fire in the chimney is well-lit, a rainstorm actually serves to pack the pit a little tighter, causing the pile to burn well, but faster.

27. What happens after the charcoal is made in the woods?

After the charcoal had been raked out at the hearth and allowed to cool, it was then loaded into specially built charcoal wagons and hauled to the charcoal barn (or house) next to the furnace.

28. Why does your charcoal look different from the kind I buy in bags in the store?

Most charcoal today is charcoal briquettes. Charcoal briquettes are a composite created from a slurry of charcoal, sawdust, wood scraps, coal dust, and minerals.

29. Did the colliers work year round?

Winter was a poor time to produce charcoal, so they worked from May through October.

30. You hose down the charcoal when you are raking it out. Doesn't water damage the charcoal?

Real charcoal (as opposed to briquettes) is not ruined by water

31. Why use charcoal pits when there were charcoal kilns available?

A charcoal kiln is a permanent structure made of stone or brick. While they are easier to use, they are expensive, and the wood must be transported to the kiln. A charcoal pit can be constructed near the wood.

32. How much charcoal will a pit produce and how much wood is in the pit?

A large charcoal pit might contain 30 cords of wood. A good collier might produce 35 to 40 bushels per cord.

33. Who cut all the wood and how much wood was harvested over a year?

Throughout the furnace's history, woodcutters were the largest group of furnace employees. Of the 213 workers on the payroll from 1835 to 1837, 112 were woodcutters. The annual requirement for charcoal at Hopewell consumed 6,000 to 7,000 cords of wood, or 200 acres of woodlands each year.

34. Did all that woodcutting lead to deforestation in the area?

The forest was cut using a system called sustained yield. This allowed only a small portion of the forest to be cut each year, and then that area would be allowed to grow back over time.

Tom Straka is a forestry professor at Clemson University in South Carolina. He is also a volunteer collier at Hopewell Furnace.

Charcoal from the charcoal pit in a traditional charcoal basket. Notice the structure of the wood is still visible, even the wood grain/Tom Straka

Support Essential Coverage of Essential Places

Support Essential Coverage of Essential Places

Comments

Isn't charcoal just burnt wood? And if so isn't its fire potential already used?

Charcoal is the ~pure carbon left when wood is burned in an oxygen deprived envrionment: "

Charcoal is made by partially burning wood in the absence of oxygen. This "carbonization" involves the regulation of air flow to the burning wood. Volatile gases from the wood are burned, leaving almost pure carbon. Charcoal has great advantages over wood in the smelting process: not only does it burn twice as hot as wood, it is also lighter than wood and thus cheaper to transport to the smelter." from: https://foresthistory.org/wp-content/uploads/2016/12/2013_History_Road.p...